One thing led to another and the decision was to re valve and re spring. First I fitted linear potentiometers on all 4 corners and calibrated shock and wheel travel. As mentioned on the previous S2000 engine page, we already had designed and made a custom Motec ADL3 harness which plugs into any Haltech Elite or Platinum CAN bus for professional data logging and analysis. This system combines all the Haltech engine data with GPS mapping, and a lab grade 3 axis accelerometer. The Motec ADL3 is fully optioned with Motec I2 Pro analysis giving the customer the same analysis capabilities as V8 Super car Teams. Using the analysis software developed for the Quantum GP700 hyper car a short drive was datalogged and the data studied in detail. We also corner weighted the car "as delivered" and measured caster, camber and toe settings to understand his previous suspension tuners settings. |

One of the rear linear potentiometers fitted on the S2000. |

|

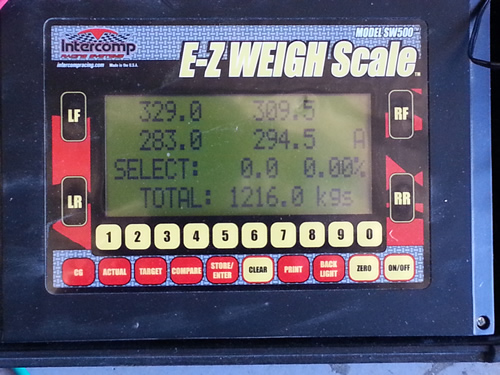

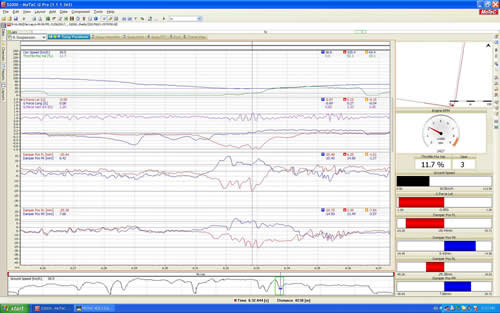

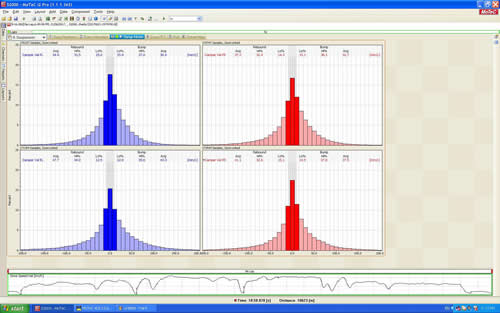

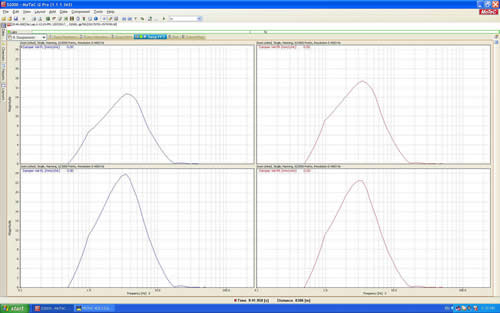

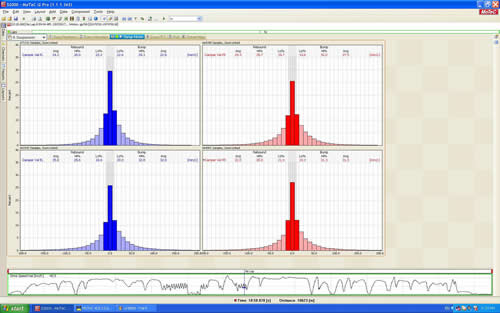

His "as delivered" corner weight settings without a driver. Surprisingly uneven as the right rear is already too heavy before any driver's weight. Above are the "as delivered" wheel travel from each linear potentiometer at 1G cornering and that's on the sliding limit of his setup on cold street tyres. (Winter here and ambient was 7degs C). The car "as delivered" was a real handful to drive on the limit. From a drivers perspective it appeared to skip across the road and was impossible predict how badly or when this would occur as even the smallest bump or camber change would set this effect in motion. Logging was interesting as you can clearly see 0.4 Vertical G Force (40% of gravity) being induced by the shocker failing to absorb and control the spring energy as the load comes off that damper/spring during cornering. For the driver this was very unsettling which was how I felt driving the car. We have logged position at 500 times per sec so it's a simple matter to calculate velocity. A short 9 minute drive ends up with 275,000 logged data position points! Aren't computers wonderful.... These are histograms for each corner of wheel travel. Velocity in mm/s in compression and rebound scaled by %. We use many other graphs and maths functions during the analysis of the "as delivered" suspension package. This write-up is just a glossary so much of our intellectual property analysis is not presented. Next everything gets stripped down. The standard shims are removed with sizes and thickness recorded. From our analysis decisions about new spring rates are made and springs ordered. |

After assembling the suspension, we set toe, camber and caster to our preferred settings. The car was then corner weighted with the driver in the photo below. |

So how did we go? Well below a position/force log after valving and spring rate changes. The car was driven at first light after a deep frost. There was still ice in puddles by the side of the road.....The temperature was 2 degrees C. This is the first corner we attempted and there was still grip left at 1.15G Lateral. The second attempt was 1.25G and at that G force the car was getting loose but easy and fun to control with no tyre temperature. Handling was neutral with slight throttle over steer if driver induced so I had a huge smile!

|

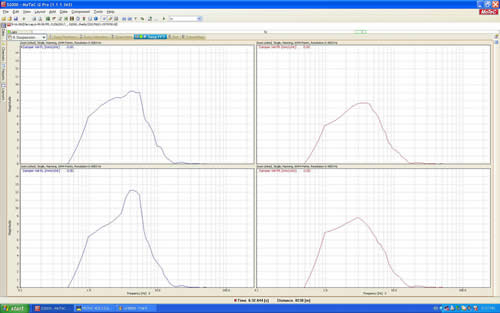

After studying the logged data and reviewing the shim stacks and piston head design, our new valving was installed. The original linear valving was replaced with our concepts developed from 20+ years of dirt bike suspension valving. Not surprisingly the harsh bumps and huge range of conditions a dirt bikes sees requires complex shock design to work well. Dirt bike suspension is 10 years + more advanced than cars in my opinion. After valving FFT is above. Logging from the first drive of the new Jaydee valving before clicker adjustments and spring preload trimming the travel used.

Next we go to Winton Raceway to see the effects on lap times. Our first test results are below.

This is our current September 2017 setup with over a 2 second inmprovement. Update 9-5-2019 In the Owners words.. "Fastest JDM street car and Fastest naturally aspirated at

|

Jeff during business hours. 0420 355 307 email: jeff.david@quantumGP700.com.au

|

|